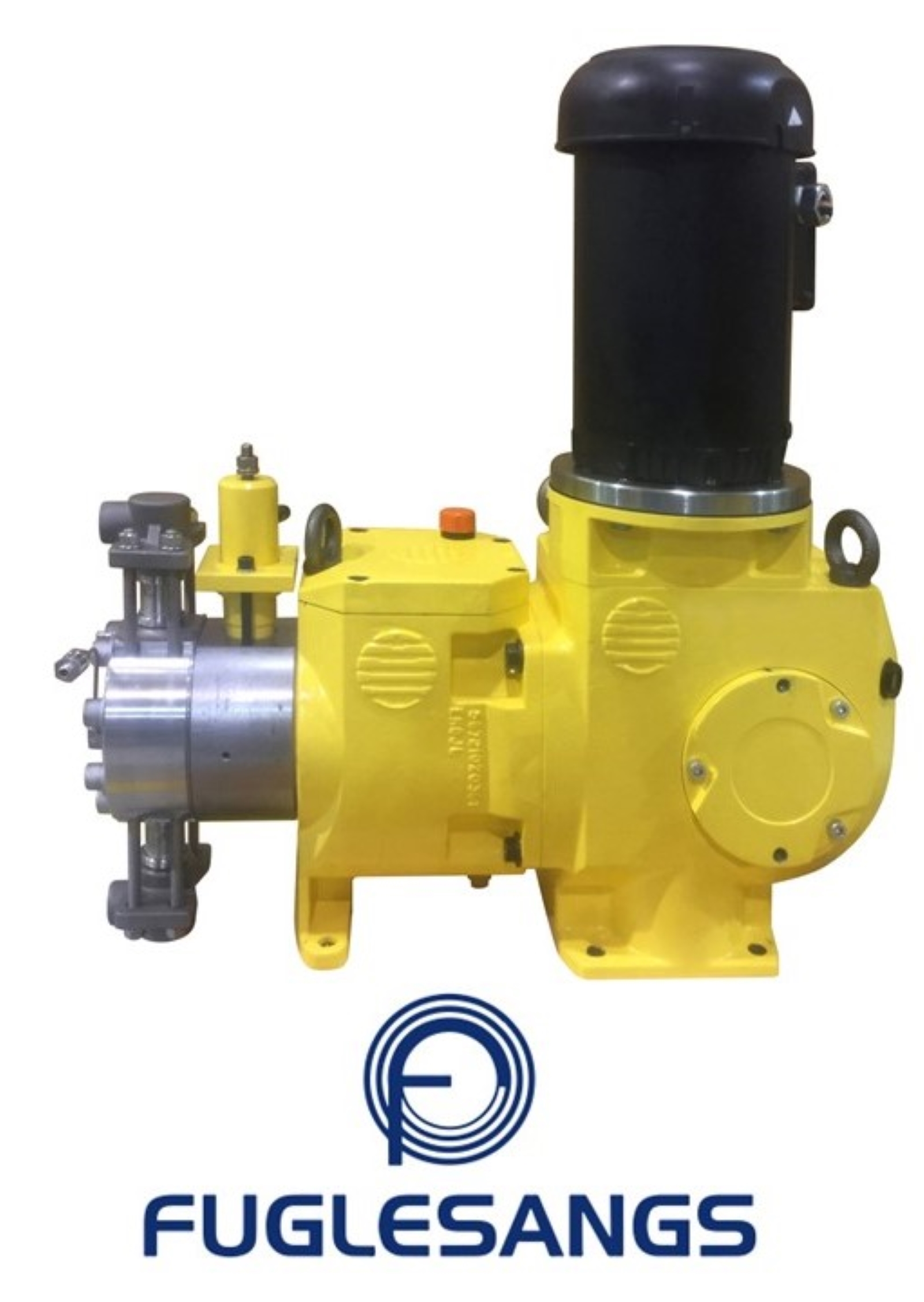

Primeroyal PH

Critical-Process Applications Reach Higher Pressures

Main benefits

- Compliant with API 675 standards

- Adaptability and accuracy: capacity adjustable while running and stopped.

- Suitable for most fluids used in industrial processes

- Pressure up to 690 bar

- Flow up to 948 L/h

- NORSOK Materials

DATA SHEET QUOTE

Product description

PRIMEROYAL® metering pumps are versatile, reliable pumps that consistently and accurately inject chemicals. The pumps’ field-proven design enables precise control of the pump delivery rate with a +/-1% steady state accuracy ranging from 10 to 100% of the nominal flow rate. They feature a compact, variable eccentric drive that changes the stroke length by repositioning the center of the shaft in the eccentric. Model PH provides accurate dosing of a broad spectrum of fluids used in many industrial processes due to their modular design, which offers several types of liquid ends, capacity control, and other configuration options to meet the specific requirements of your process application.

• Compliant with API 675 standards

• Adaptability and accuracy: capacity adjustable while running and stopped (stroke micrometric adjustment, ten (10) turns only from 0 to 100%, graduation scale in %)

• Space constraints: minimized footprint and weight, available in vertical or horizontal motor configurations

• Suitable for most fluids used in industrial processes: many stroke speeds for accurate dosing

• Modular design to precisely fit your needs: multiple options for liquid ends, check valves, connection types, and control

• Multiplexing capability: provides cost savings in power consumption and asset footprint while reducing pulsation and required NPSH, capable of injection several different products at multiple specific flow rates

• Long life: high-quality materials engineered to a robust and proven construction, oil bath lubrication to ensure reliability during continuous operation

• Safety: leak-resistant diaphragm liquid ends with service life over 20,000 hours. Operates in the most extreme conditions: specific

• Operates in the most extreme conditions: specific configurations to operate in saline/offshore conditions, desert, or low temperature environment

• Global design: complies with major global certifications and systems: ATEX, NACE, SASO, Customs Union, etc.

• Overpressure protection: integrated safety valve to protect the pump on diaphragm liquid ends

• Efficient maintenance: the patented Mechanically Actuated Refill System (MARS) eliminates the need for adjustments the refill valve

Technical

• Packed plunger, PTFE or metallic diaphragm liquid ends available

• Liquid end body in 316L SS, 17-4P-H, PVC or PVDF. Other materials such as Alloy 20, Hastelloy®, super Duplex available upon request

• Diaphragms in PTFE or 316L stainless steel; plunger in ceramic

• Six (6) stroke speeds/gear ratios available with 50 Hz motor: 38, 57, 99, 115, 144 and 180 spm. Five (5) stroke speeds / gear ratios with 60 Hz motor: 48, 69, 119, 138 and 173 spm

• Manual or electrical stroke length adjustment

• IEC or NEMA mounting, motor for frequency variation

• Electric equipment for non-hazardous or hazardous area, large variety of protections and insulations

• Conforms to ATEX CE EX II 2G/D c T4/T3 with ATEX motors

• Optimum protection for critical processes or pumped fluids: double or triple diaphragm, diaphragm failure detection, temperature probes

• Special valves for any type of fluid (including concentrated sulphuric acid and slurries)

• Remote head, cooling/heating jacket to operate in processes requiring low/extreme fluid temperatures

• Full set of connections: screwed or flanged connectors(ANSI, DIN or ISO)

• Wide range of accessories available to complete your dosing installation

Technical data

• Flow rate up to 948 L/h

• Pressure up to 690 bar

• Temperatures -10 to + 55 degrees C

• Low T design -40 to + 55 degrees C

Applications

• Chemical / Petrochemical: chemical injection of additives, injection of co-catalyst such as TEAL for polyethylene and polypropylene, injection of sulphuric acid into water to produce diluted sulphuric acid

• Food and Beverage: injection of enzymes in starch production, injection of caustic soda for process water neutralization in refining and distilling applications

• Oil and Gas: chemical injection of biocide, corrosion / scale inhibitors, hydrogen sulfide (H2 S) scavengers to protect piping and other assets and maintaining production rates, transfer of steam condensate

• Refinery / Downstream: chemical injection for separation and treatment of refined products, injection of paraffin inhibitor into fuel storage tanks

• Water / Wastewater Treatment:

- Water Treatment: disinfection, fluoridation, coagulation / flocculation, pH control, water conditioning before and / or after RO treatment in desalination plant

- Industrial Water Treatment: protection of installation such as boilers and hydraulic systems to prevent scale and corrosion.