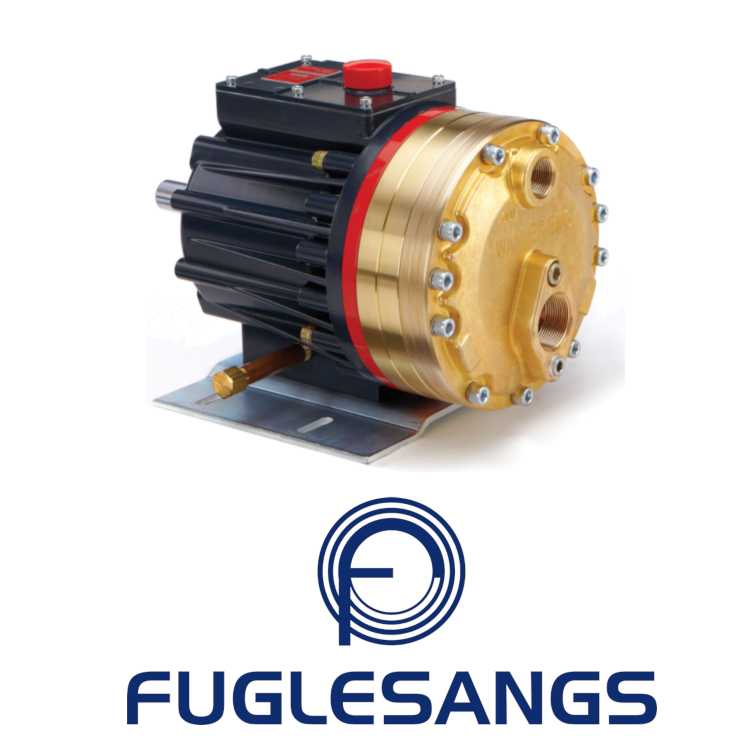

WANNER HYDRA-CELL PRO G25

High pressure pump

Main benefits

- Sealless design, small footprint, high volumetric efficiency.

- Used in applications such: High pressure washing, chemical processing, high pressure machine tool coolant, metering and dosing chemical additives, sealless design, small footprint, high volumetric efficiency,

- Ideal for Mining, oil production and refining, paper and pulp, reverse osmoses, water and wastewater

DATA SHEET QUOTE

Product description

This high pressure pump design is exclusive to WANNER HYDRA-CELL PRO with their sealless piston membrane pump design. As a high pressure pump the series can deliver up to 175bar and have maximum flowrate of 250 l/min, where the performance for the WANNER HYDRA-CELL PRO G25 has a maximum flowrate of 76 l/min at maximum of 69 bar.

Reciprocating pumps are known for their capabilities for high pressure and accurate flowrates, but also seal failures and downtime consequently. This is history with the WANNER HYDRA-CELL PRO G25 high pressure pump with their sealless piston membrane pump design. The pump allows for a more accurate and linear flowrate according to API 674.

The WANNER HYDRA-CELL PRO G25 pump can be delivered with Atex certificate, allowing the high-pressure pump with its sealless piston membrane pump design to be installed in hazardous areas where leakage through the mechanical seals is an issue.

Classificaton; ATEX 94/9/EC Certified, Category 2, Zone 1. This maintained with a constant monitoring of the oil level in the bearing housing.

The WANNER HYDRA-CELL G25 pump comes with a big variety in diaphragm materials, with the most important to be: NBR, FKM, EPDM, PTFE. Pump head materials range from: BRASS, CAST IRON, DUCTILE IRON, SS316L, HASTELLOY, DUPLEX, SUPER DUPLEX, POLYPROPYLENE, PVDF.

With this wide range of materials, we can build a pump that meet almost any application where there is a need for a high-pressure pump with sealless piston membrane pump design.

Applications for the Hydra-Cell G25 is many, coolant high pressure pump for CNC machines where this pump is one of the work horses in the G- series and is a best seller.

Process plants where chemical injection is provided at both high and lower pressures and accurate low pulsing linear dosing, with the need for no leakage.

SAVE TIME, FOR A QUICKER REPLY FILL OUT OUR PUMP APPLICATION FORM NOW!