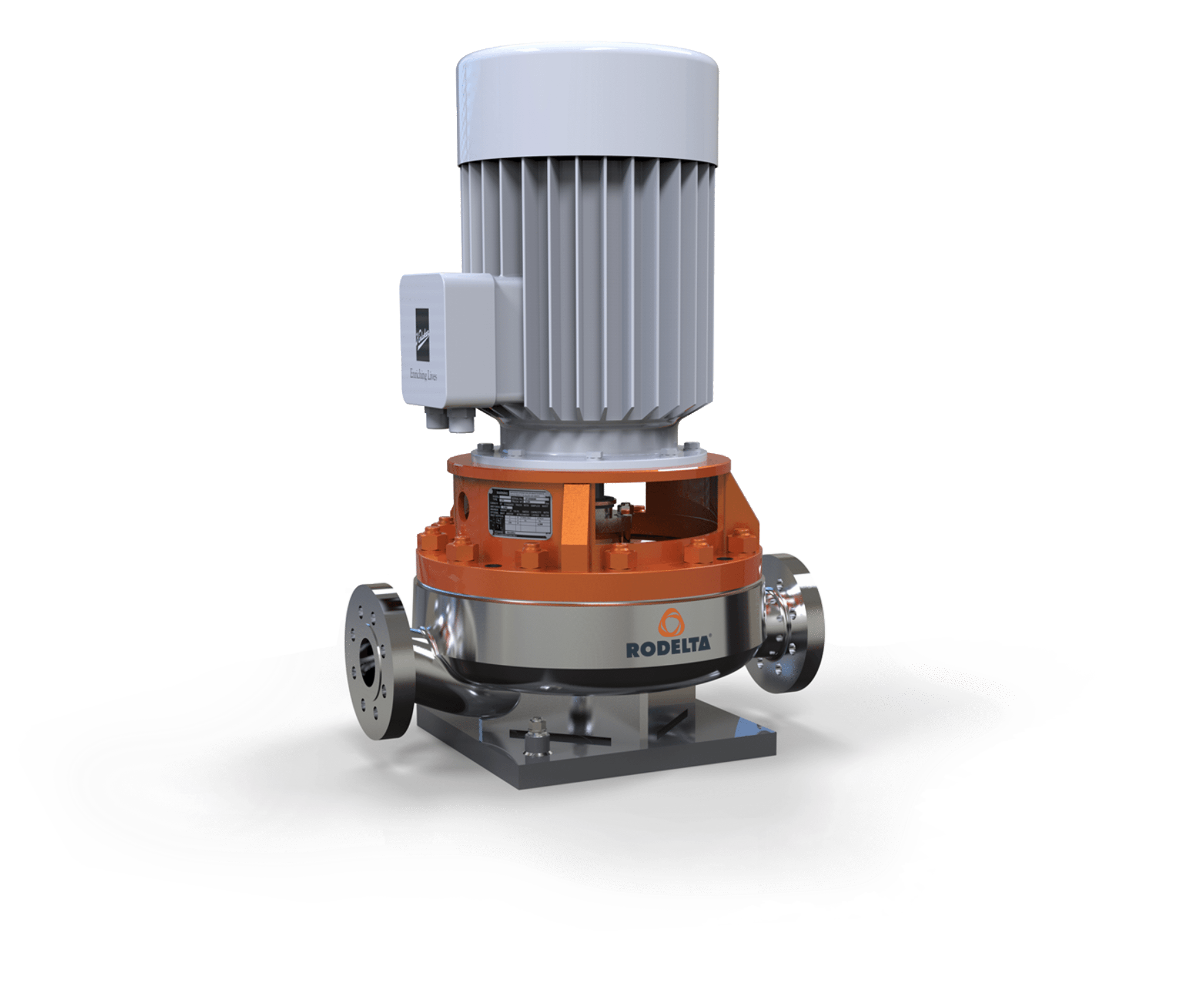

Rodelta ETL OH5

Rodelta ETL (Close Coupled OH5)

Main benefits

- According API610 (OH5) Full 12th edition (zero deviations)

- Low radial loads due to diffuser design give long bearing and seal life

- Reduces minimum flow requirements

- High efficiency at any duty due to diffusor technology

- Alignment free construction

DATA SHEET QUOTE

Product description

The pump type ETL (OH5) vertically inline mounted, close coupled, radial split case, single stage, single suction, heavy duty centrifugal process pumps. The design complies with the latest edition of the American Petroleum Institute standard 'Centrifugal Pumps For General Refinery Services', also known as API 610/ ISO13709.

The inline configuration is a compact pumping solution with mounting the impeller to an extended motor drive shaft presents a very compact pumping solution. The ETL (OH5) offers a space saving footprint and eliminates expensive baseplates. (This pump is also available in long coupled pump type ETLS (OH3) for high temperature applications)

Specifications:

- Capacity up to 600m3/hr (50Hz, 3000 Rpm)

- Head up to 290m (50Hz, 3000 Rpm)

- Suitable for liquid Temperature: Up to 250ºC depending on Pump size

- Sealing Arrangement: mechanical seals

- Flange rating: CI. 150/300/600 or DIN

Applications:

- Fluid handling in oil refineries and petrochemical industry

- High temperature and high pressure critical applications in chemical and allied industry

- Upstream, pressure booster

- Midstream, process transfer, bottom reflux, propane/butane/LPG handling, diesel oil/gasoline/naphtha/lube oils etc., sodium carbonate/caustic sour water, MEA/DEA/TEA

- Fertilizer, carbamates/lean and semi lean solutions, NH3 feed, other removals

- Power plant, Hot water circulation, condensate transfer, fuel oil

- Onshore/Offshore installations