Ground-breaking new offer!

Leader of Equinor’s Killingøy base Jan Olav Berge, and many other oil-companies, sees new opportunities for repairs and corrosion protection on platforms in the North Sea.

Robotized Subsea Wrapping Technology – also in the Splash Zone

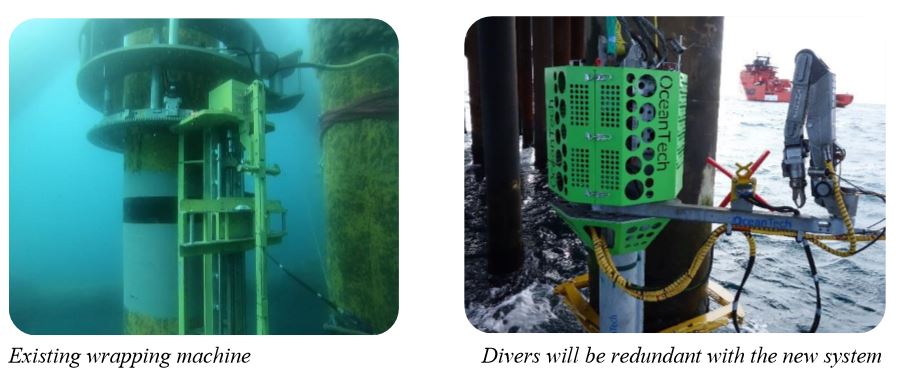

Fuglesangs AS and OceanTech Innovation AS has entered into a partnership agreement. The two companies are offering to do Subsea repairs on steel structures such as caissons, conductor-pipes and riser-pipes etc., by use of a robotized installation method. Fuglesangs, who is the system supplier, successfully completed a repair job of 3 caissons in the Splash Zone at Equinor’s Oseberg field in 2018. Unfortunately, the use of divers resulted in unnecessarily high costs for the project. Divers require calm seas in order to work, and calm seas is a rare thing in the North Sea. Jan Olav Berge in Equinor confirms that a robotization of the already proven repair technology is very interesting and adds to the toolbox a method that can be both cost-effective and flexible.

Many of the older offshore installations have major issues related to corrosion and structural damages, especially in the Splash Zone (+5 to -10 meters). There are cases where caissons have broken off and fallen to the seabed, which can damage other Subsea installations and stop production on the field. Most oil-companies are today choosing to replace the whole damaged structure (which is very costly) or to repair it using different kinds of clamping solutions. 3X Engineering in Monaco, who is a supplier to Fuglesangs, have developed a wrapping solution especially for the colder North-Sea waters. With a lifetime of up to 20 years, incredible adhesion and the ability to rebuild structural strength, this is a unique technology that can now be installed without divers.

OceanTech has since 2007 developed robotized access tools for operations in the Splash Zone on offshore installations. This work was started under Linjebygg Offshore, where the SplashZone division was bought by OceanTech in 2017. By utilizing robust and flexible access tools, OceanTech has successfully completed mechanical work, inspections and maintenance that require a high degree of precision.

The partners will be able to do Subsea repairs in both the Splash Zone and in deeper areas, without using divers or support vessels. All stages of the wrapping process, including the removal of marine growth, inspection, grit blasting/UHP-waterjetting, priming and wrapping will be done using manipulator arms and a wrapping machine that are especially developed for the task. The operations are monitored and executed from a topside control unit. This will not only reduce costs significantly, but also the time needed to complete the job will be reduced with up to 50%. Because Fuglesangs and OceanTech has all the equipment and personnel needed, it will also be possible to mobilize on short notice.

Fuglesangs was established in 1916 and is located at Alna in Oslo. The company has more than 30 years’ experience with polymer coatings for industrial applications and has recently undertaken large subsea wrapping jobs in the North Sea for Equinor. FAS has a 2000 m2 modern workshop. In addition to inhouse engineering staff, considerable technical knowledge is available from a number of suppliers.

OceanTech was established in 2017 through a buyout of a department in Linjebygg. The company is located at Nyhavna in Trondheim. OTAS has more than ten years of experience with specialized horizontal and vertical access tools for work in the splash-zone on oil platforms. With their 5000 m2 space including Dora 2, they have the possibility to make full scale tests, also under water, of access tools, robotization equipment and software.

Contacts:

- Hans Peter Fuglesang hpf@fuglesangs.no +47 915 42 002

- Bernt Schjetne bernt.schjetne@oceantech.no +47 482 72 360